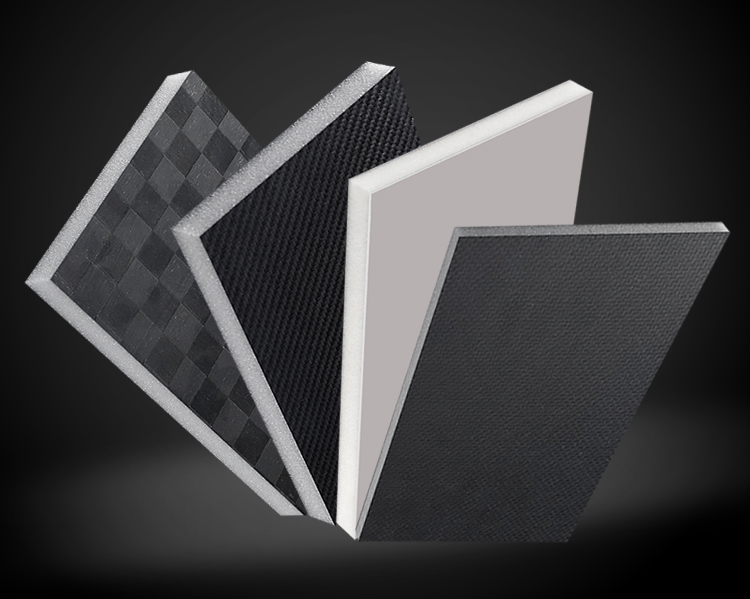

The core material foam can be divided into rigid foam, soft foam, semi-rigid or semi-soft foam. The core material foam plastic is also called porous plastic, a plastic with numerous micropores inside made of resin as the main raw material. It is widely used as heat insulation, sound insulation, packaging materials and car and ship shells. Core foam plastics can be divided into soft, rigid and semi-rigid foams in between according to their flexibility.

Rigid foam plastics can be used as thermal insulation materials and sound insulation materials, insulation materials for pipes and containers, floating materials and shock-absorbing packaging materials, etc.; soft foam plastics are mainly used as cushioning materials, foam artificial leather, etc. Commonly used foam plastics are polyurethane, polystyrene, polyvinyl chloride, polyethylene, phenolic foam and so on. The core material foam plastic is also called porous plastic, a plastic with numerous micropores inside made of resin as the main raw material. Lightweight, heat-insulating, sound-absorbing, shock-proof, corrosion-resistant, and can be divided into soft and hard.

Compared with pure plastic, core foam plastic has low density, light weight and high specific strength. Its strength increases with the increase of density. It has the ability to absorb impact load, excellent cushioning and shock absorption performance, sound insulation and sound absorption performance. Low conductivity, good thermal insulation performance, excellent electrical insulation performance, corrosion resistance and mildew resistance. Flexible foam plastic has excellent elasticity and other properties, and is widely used as heat insulation, sound insulation, packaging materials and car and ship shells.

Plastic with many tiny pores in the content. It is made by mechanical method (inject air or carbon dioxide while performing mechanical stirring to make it foam) or chemical method (add foaming agent). There are two types: closed cell type and open cell type. The pores in the closed cell type are isolated from each other and have floating properties; the pores in the open cell type are connected to each other and have no floating properties. It can be made of polystyrene, polyvinyl chloride, polyurethane and other resins. It can be used as heat insulation and sound insulation material and has a wide range of uses.