Summary:The core material foam plastic uses two boards and then sand...

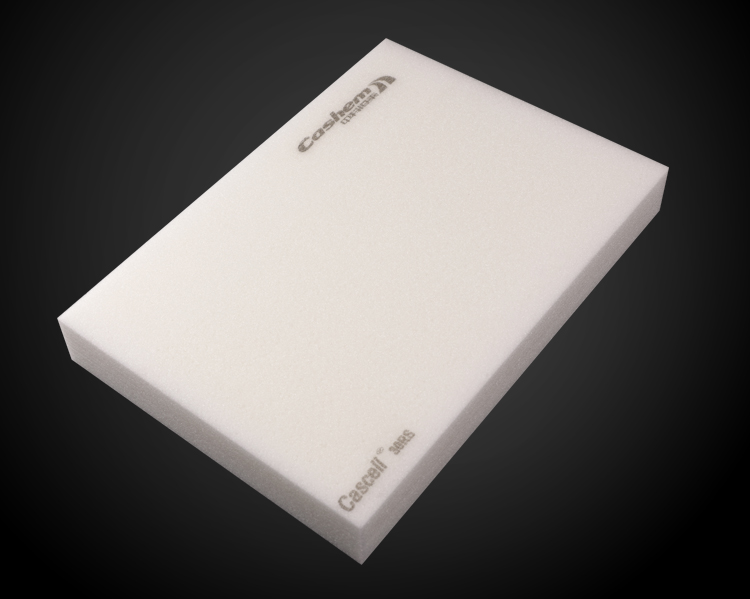

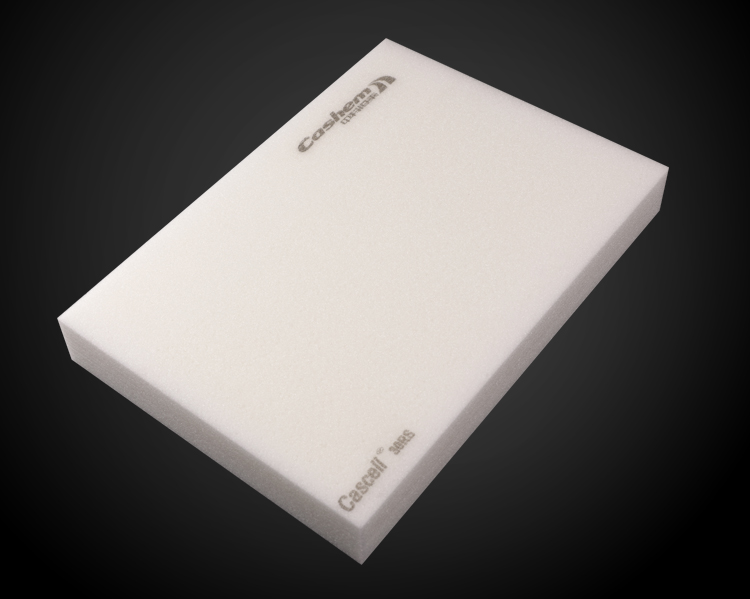

The core material foam plastic uses two boards and then sandwiches the foam in the middle. The purpose of this is to meet the thermal insulation of buildings and the effect of sound insulation. It is not difficult to process, the material in the middle is mainly made of foam, and then processed into a sandwich panel. This kind of core material foam gives full play to the unique properties of rock wool core material. It has the characteristics of fire prevention and good thermal insulation effect. It has the unique characteristics of heat insulation, sound absorption and sound insulation.

This kind of core material foam plastic is made of color steel rock wool sandwich panel, which is processed into a whole by rock wool and steel plate, so that the board can meet the requirements of building thermal insulation, sound insulation, fire prevention, and this kind of The safety of the material is also relatively high, so that the goals of high quality, high efficiency, reliability and safety can be achieved, so this material is also used by everyone. The polystyrene core foam is made of colored steel plate as the surface, and closed-cell self-extinguishing

polystyrene foam as the core.

A new type of high-efficiency composite building material made of high-strength adhesives after the color steel plate is pressed by an automatic continuous forming machine. It has the characteristics of thermal insulation, waterproof one-time completion, fast construction, durable, beautiful and so on.

The core material foam plastic has the advantages of light weight, 1/20~1/30 of the weight of the concrete roof, thermal insulation, thermal conductivity value of 0.034W/mk, fast construction speed, no wet work, no secondary decoration, and the construction period can be It is shortened by more than 40%, the color is bright, no surface decoration is required, and the maintenance period of the anti-corrosion layer of the color galvanized steel plate is 15-30 years.