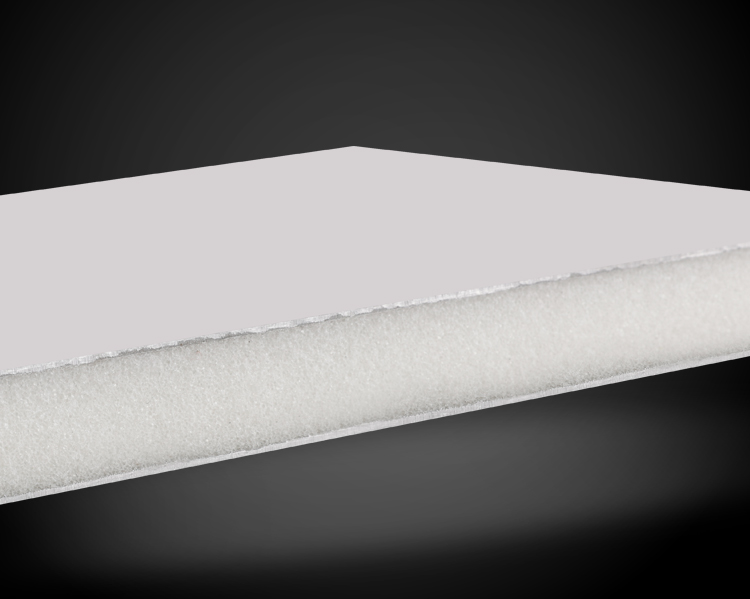

The sandwich materials used for composite sandwich structures mainly include: rigid foam, PMI foam, honeycomb and balsa wood. Rigid foam mainly includes polyvinyl chloride (PVC), polyurethane (PU), polyetherimide (PEI), acrylonitrile-styrene (SAN or AS), polymethacrylimide (PMI), foaming Polyester (PET) etc. Honeycomb sandwich materials include glass cloth honeycomb, NOMEX honeycomb, cotton cloth honeycomb, aluminum honeycomb and so on.

The honeycomb sandwich structure has high strength and good rigidity, but the honeycomb is an open-cell structure, and the bonding area with the upper and lower panels is small, and the bonding effect is generally not as good as foam. Balsa sandwich material is a natural product. The common balsa sandwich cores on the market are mainly produced in plantations in South America. Due to climatic reasons, balsa wood grows very fast in the local area, so it is much lighter than ordinary wood, and its fiber With good strength and toughness, it is especially suitable for composite sandwich structures.

The application fields of sandwich materials are broad, involving energy, aerospace, shipbuilding, transportation, construction and other fields. Sandwich material is one of the key materials for wind power blades. In order to increase structural rigidity, prevent local instability, and improve the load resistance of the entire blade, sandwich structures are generally used at the leading edge, trailing edge and shear ribs of the blade.

The core materials used for wind turbine blades mainly include PMI foam, Balsa balsa wood and PET foam. The typical design plan is to use Balsa balsa wood (with a density of 150 kg/m3) with higher strength for the part close to the root of the leaf where the load is larger, and cross-linked PVC foam (with a density of 60 kg/m3) for the load In the smaller part near the tip, the thickness of the sandwich material gradually decreases from the root to the tip. There are also blade manufacturers that only use Balsa or foam.