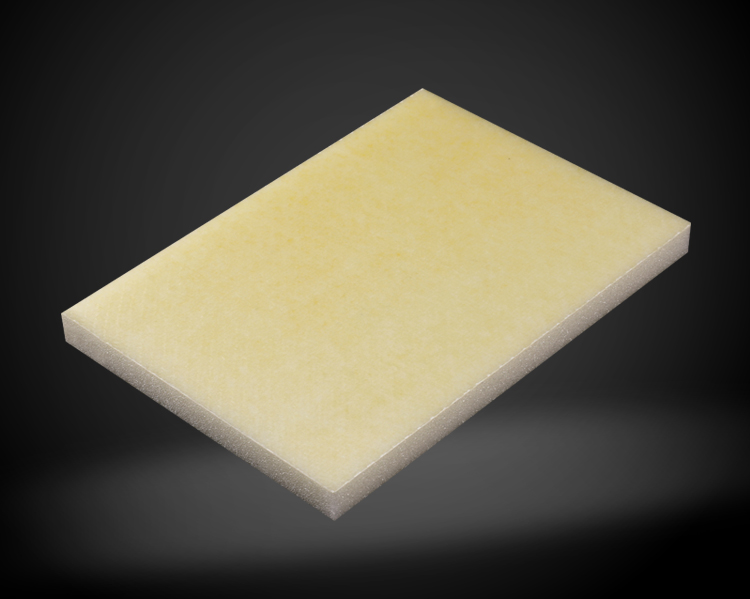

PMI foam is made by heating methacrylic acid/methacrylonitrile copolymer board and foaming. During the process of foaming the copolymerized sheet, the copolymer is converted into polymethacrylimide. The foaming temperature is above 170oC and varies by density and type.

Now, the world's PMI foam products are ROHACELL series products produced by Degussa, Germany. In the linear elastic state, when the foam is made of liquid members (there are many such foams, such as polyurethane foam), the surface tension The material can be pulled towards the edge, leaving only a thin film across the hole surface, which is easy to break. Thus, although the foam has initially closed cells, its stiffness is entirely derived from the cells and ribs, and its modulus is equivalent to that of an open-cell foam. However, the pore surfaces of PMI foam materials are composed of real solid parts, and these pore surfaces add stiffness to the porous body.

The compression deformation mechanism of closed-cell foam consists of three parts: the bending of the cell wall, the shortening of the edges and the extension of the membrane, and the pressure of the enclosed gas. The structural advantage of the PMI foam sandwich structure In the sandwich structure, the PMI foam material can be used as a structural unit. In the past, foam was generally only used as a filling material without considering the contribution of its strength and stiffness to the structure. The main reason is that the foam materials used in the past, such as PUR foam, are generally foamed in the cavity after the structure is completed, so the quality, uniformity and mechanical properties of the foam are difficult to ensure.

PMI foam adopts a unique solid foaming technology, which can ensure the quality, uniformity and mechanical properties of the foam. PMI foam is a polymer rigid foam material with high specific strength and specific stiffness. By calculation, if the PMI foam is used as the structural unit of the sandwich structure, the panel can cut 1-2 layers of carbon fiber layup. PMI foam sandwich structure can be used as a structural sandwich structure, and the application field breaks through the traditional view of non-structural sandwich structures such as honeycombs in the past.

PMI foam In the field of medical radiation equipment, carbon fiber composite material is used as the panel, and the carbon fiber PMI foam sandwich panel with a "sandwich" structure with a foam core in the middle is used as the bed board that supports the patient and transmits rays. Its X-ray transmission performance, imaging The clarity, strength and rigidity are obviously better than those of traditional bed boards such as polycarbonate and phenolic resin boards, which play an important role in improving the overall performance of the equipment.